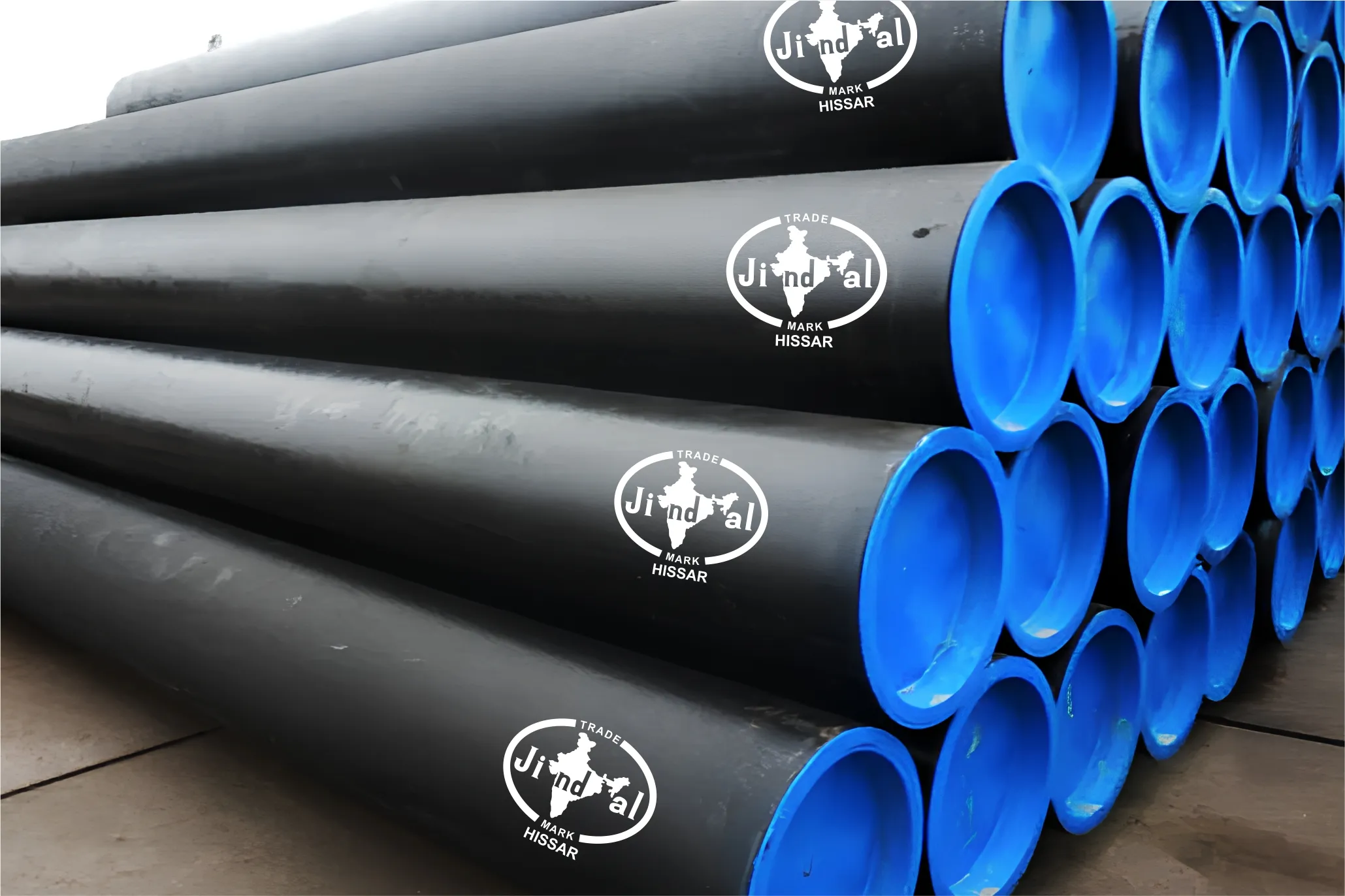

JINDAL-HISSAR MANUFACTURES PIPE SIZE 150mm NB

to 400mm NB, BOTH BLACK & GI. BIS LICENCE

- ERW STEEL TUBES FOR WATER WELLS

CONFORMING TO IS: 4270 : 2001

PLAIN END CASING PIPES Grade Fe 410 and Fe 450 - ERW STEEL TUBES FOR WATER WELLS CONFORMING TO IS: 4270 : 2001

- PLAIN END CASING PIPES

- Higher Thickness other than the Specified may also be manufactured as per Customer requirement.

- JINDAL-HISSAR MANUFACTER to 300mm NB, BOTH BLACK & GI, “‘ BIS LICENCE NO. CM/L- 9517082

- JINDAL-HISSAR MANUFACTURES PIPE SIZE 15mm NB to 350mm NB, BOTH BLACK & GI. BIS LICENCE NO. CM/L – 0641038

- STEEL TUBES FOR MECHANICAL AND GENERAL

- ENGINEERING PURPOSES MARK TECHNICAL DATA OF BLACK & GALVANISED PIPES SPECIFICATION IS:360 l: 2006

- ERW (INCLUDING HFIW) STEEL TUBES FOR IDLERS FOR BELT CONVEYORS

- TECHNICAL DATA OF PIPES SPECIFICATION AS PER IS:9295 – 1983 DIMENSIONS & NOMINAL MASSES

Manufacturing Process

The process utilises the latest technology and modern equipments for producing high Quality ERW Pipes

1. Slit Preparations

HR Colis are slitted to predetermined widths for each size of pipe and thickness. Slitted coil is uncoiled at the entry of ERW mill and the ends are sheared and welded one after another to make it single endless strip.

2. Forming

Slitted coil are initially formed into ‘U’ shape and then into a cylindrical shape with open edges using a series of forming rolls.

3. Welding

The open edges are heated to the required temperature through high frequency low voltage high current and press welded by forge rolls making perfect and strong butt-weld without filler materials.

4. Debeading

Weld flash on top and inside (if need) is trimmed out through carbide tools.

5.

Seam Annealing

Whenever required, welding portion and heat affected zone is put to normalising with medium frequency normaliser and then cooled down in air cooling bed.

6. Sizing & Cutting

After water quenching, slight reduction is applied to pipes with sizing rolls to give them desired accurate outside diameter.

Pipes are cut to required lengths by flying cut off disc/saw cutter.

7. Facing and Bevelling

The pipe ends are faced and bevelled by the end facer.

All the processes are continuous with auto arrangements. These plain ended tubes go for further processing as per the customer need like galvanizing, threading, black varnishing etc.

8. Packing

Finished pipes are bundled in desired number of pieces as per customer’s requirement and packed properly to ensure freshness till delivery.