| Class Designation: 3000 Lbs | Dimensions As Per ASME B16.11-2011/ IS: 4712:2011 (Class 20) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | Socket Bore Dia B | Bore Dia of Fitting Dia D | Socket Wall Thickness C | MIN. Depth of Socket J | Center to Bottom of Socket A | Body Wall Thickness G | ||||

| Inch | MM | Min. | Max. | Min. | Max. | Min. | Min. | Min. | Max. | Min. |

| 1/8″ | 6.00 | 10.80 | 11.20 | 6.10 | 7.60 | 3.18 | 10.50 | 8.00 | 9.00 | 2.41 |

| 1/4″ | 8.00 | 14.20 | 14.60 | 8.50 | 10.00 | 3.30 | 10.50 | 8.00 | 9.00 | 3.02 |

| 3/8″ | 10.00 | 17.60 | 18.00 | 11.80 | 13.30 | 3.50 | 10.50 | 8.00 | 9.50 | 3.20 |

| 1/2″ | 15.00 | 21.80 | 22.20 | 15.00 | 16.60 | 4.09 | 10.50 | 11.00 | 12.50 | 3.73 |

| 3/4″ | 20.00 | 27.20 | 27.60 | 20.20 | 21.70 | 4.27 | 13.50 | 13.00 | 14.50 | 3.91 |

| 1″ | 25.00 | 33.90 | 34.30 | 25.90 | 27.40 | 4.98 | 13.50 | 14.00 | 16.00 | 4.55 |

| 1.1/4″ | 32.00 | 42.70 | 43.10 | 34.30 | 35.80 | 5.28 | 13.50 | 17.50 | 19.50 | 4.85 |

| 1.1/2″ | 40.00 | 48.80 | 49.20 | 40.10 | 41.60 | 5.54 | 13.50 | 20.50 | 22.50 | 5.08 |

| 2″ | 50.00 | 61.20 | 61.70 | 51.70 | 53.30 | 6.04 | 17.00 | 25.50 | 27.50 | 5.54 |

| 2.1/2″ | 65.00 | 73.90 | 74.40 | 61.20 | 64.20 | 7.67 | 18.00 | 28.50 | 31.00 | 7.01 |

| 3″ | 80.00 | 89.80 | 90.30 | 76.40 | 79.40 | 8.30 | 18.00 | 32.00 | 34.50 | 7.62 |

| 4″ | 100.00 | 115.20 | 115.70 | 100.70 | 103.80 | 9.35 | 19.00 | 41.00 | 43.00 | 8.56 |

| All Dimensions in MM | ||||||||||

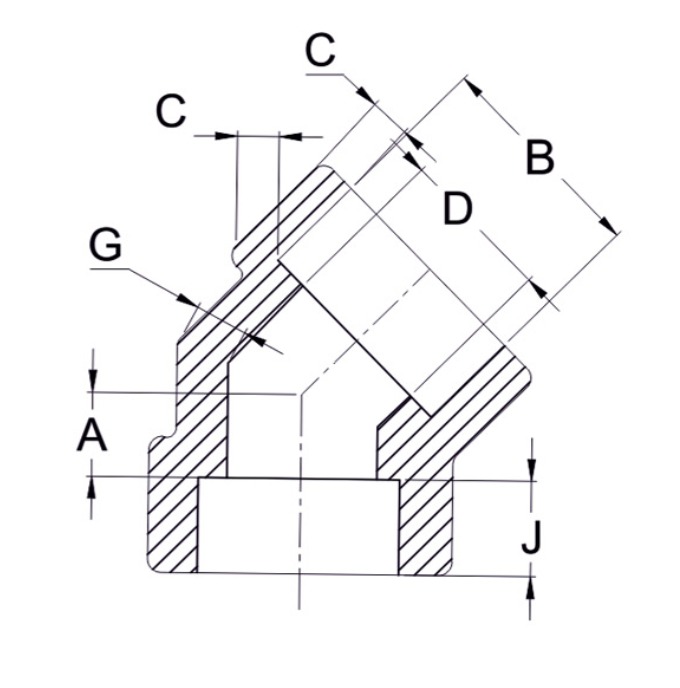

Socket Weld Elbow-45° Forged 3000 LBS

| Class Designation: 3000 Lbs | Dimensions As Per ASME B16.11-2011/ IS: 4712:2011 (Class 20) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | Socket Bore Dia B | Bore Dia of Fitting Dia D | Socket Wall Thickness C | MIN. Depth of Socket J | Center to Bottom of Socket A | Body Wall Thickness G | ||||

| Inch | MM | Min. | Max. | Min. | Max. | Min. | Min. | Min. | Max. | Min. |

| 1/8″ | 6.00 | 10.80 | 11.20 | 6.10 | 7.60 | 3.18 | 10.50 | 8.00 | 9.00 | 2.41 |

| 1/4″ | 8.00 | 14.20 | 14.60 | 8.50 | 10.00 | 3.30 | 10.50 | 8.00 | 9.00 | 3.02 |

| 3/8″ | 10.00 | 17.60 | 18.00 | 11.80 | 13.30 | 3.50 | 10.50 | 8.00 | 9.50 | 3.20 |

| 1/2″ | 15.00 | 21.80 | 22.20 | 15.00 | 16.60 | 4.09 | 10.50 | 11.00 | 12.50 | 3.73 |

| 3/4″ | 20.00 | 27.20 | 27.60 | 20.20 | 21.70 | 4.27 | 13.50 | 13.00 | 14.50 | 3.91 |

| 1″ | 25.00 | 33.90 | 34.30 | 25.90 | 27.40 | 4.98 | 13.50 | 14.00 | 16.00 | 4.55 |

| 1.1/4″ | 32.00 | 42.70 | 43.10 | 34.30 | 35.80 | 5.28 | 13.50 | 17.50 | 19.50 | 4.85 |

| 1.1/2″ | 40.00 | 48.80 | 49.20 | 40.10 | 41.60 | 5.54 | 13.50 | 20.50 | 22.50 | 5.08 |

| 2″ | 50.00 | 61.20 | 61.70 | 51.70 | 53.30 | 6.04 | 17.00 | 25.50 | 27.50 | 5.54 |

| 2.1/2″ | 65.00 | 73.90 | 74.40 | 61.20 | 64.20 | 7.67 | 18.00 | 28.50 | 31.00 | 7.01 |

| 3″ | 80.00 | 89.80 | 90.30 | 76.40 | 79.40 | 8.30 | 18.00 | 32.00 | 34.50 | 7.62 |

| 4″ | 100.00 | 115.20 | 115.70 | 100.70 | 103.80 | 9.35 | 19.00 | 41.00 | 43.00 | 8.56 |

All Dimensions in MM

High-Quality Construction for Superior PerformanceThe Socket Weld Elbow-45° Forged 3000 LBS is an industry-leading solution for creating secure and durable pipe connections in critical applications. Forged from high-quality materials and designed to meet stringent engineering standards, this fitting ensures reliability and long-lasting performance even in demanding environments. Its compact design and robust build make it an ideal choice for applications requiring smooth flow redirection at 45° angles, minimizing stress and enhancing pipeline efficiency. Exceptional Strength and Pressure HandlingBuilt to support heavy-duty applications, the Socket Weld Elbow-45° Forged 3000 LBS excels at withstanding elevated pressure levels. Rated for 3000-pound services, this fitting is perfectly suited for industries such as oil and gas, chemical processing, and HVAC systems. The forged construction enhances its strength and durability, making it resistant to wear, corrosion, and deformation — ensuring reliable performance in both high-pressure and high-temperature conditions. Precise Fit and Easy InstallationEngineered for precision, the Socket Weld Elbow fits seamlessly into piping systems, offering a leak-free, secure connection that promotes operational safety. Its socket weld design simplifies installation, requiring minimal expertise while maintaining an exceptionally tight bond between pipe and fitting. This 45° elbow not only facilitates smooth directional changes but also reduces the risk of turbulence or disruption in flow, optimizing system efficiency. Whether you’re upgrading existing systems or building new pipelines, the Socket Weld Elbow-45° Forged 3000 LBS delivers uncompromising quality, reliability, and performance, making it the ultimate choice for professionals seeking dependable pipe-fitting solutions. Superior Engineering for Demanding ApplicationsExperience the excellence of the Socket Weld Elbow-45° Forged 3000 LBS, designed to meet the rigorous needs of industrial piping systems. Engineered with precision, this pipe fitting ensures unmatched durability and performance in high-pressure environments. Crafted from premium forged materials, you can rely on its robust construction to withstand the most demanding applications. Efficient Design for Seamless InstallationThe 45° elbow design is tailored to provide an efficient and seamless directional change in your piping system. Its socket weld configuration allows for secure and leak-resistant connections, ensuring optimal functionality in your operations. Whether used in chemical processing plants, oil refineries, or power generation facilities, this fitting meets the highest industry standards. Why Choose Our Socket Weld Elbow?At 3000 LBS pressure rating, this forged elbow is built to handle extensive demands without compromising structural integrity. The smooth surface finish ensures minimal resistance to fluid flow, improving overall system efficiency. Moreover, its corrosion-resistant properties make it suitable for a wide range of media, including corrosive liquids and gases. By choosing our product, you invest in lasting reliability and improved performance. Designed for Strength and PrecisionThe Socket Weld Elbow-45° Forged 3000 LBS is meticulously engineered to provide a high-performance solution for pipe connection needs. Manufactured from forged steel, this elbow delivers robust strength and exceptional reliability, adhering to industry standards. Its 45-degree angle ensures efficient directional adjustments while minimizing flow resistance, making it an ideal choice for various applications in piping systems. Built for durability, it withstands extreme pressure settings up to 3000 LBS, guaranteeing long-lasting performance in demanding environments. Superior Construction for Industrial ApplicationsPerfectly suited for industries requiring heavy-duty components, the Socket Weld Elbow-45° enhances system integrity with its superior weldability and precise fit. Whether used in petrochemical plants, construction sites, or mechanical setups, the elbow’s forged steel construct promises optimal density and crack resistance. The 45-degree configuration ensures smooth transitions without compromising structural efficiency, making it an integral part of high-pressure piping systems. Its compact design also supports space optimization without sacrificing safety or functionality. Trusted Quality and Easy InstallationEase of installation coupled with reliability is at the forefront of the Socket Weld Elbow-45° Forged 3000 LBS. The socket weld end ensures an accurate and leak-proof connection, simplifying the process for professionals. Tested and certified to meet rigorous quality standards, this forged elbow exemplifies durability, even under extreme thermal and mechanical stress. By choosing this product, you invest in a reliable pipe-fitting solution that boosts your system’s efficiency and longevity, all while maintaining cost-effectiveness. |

||||||||||